Industrial assembly

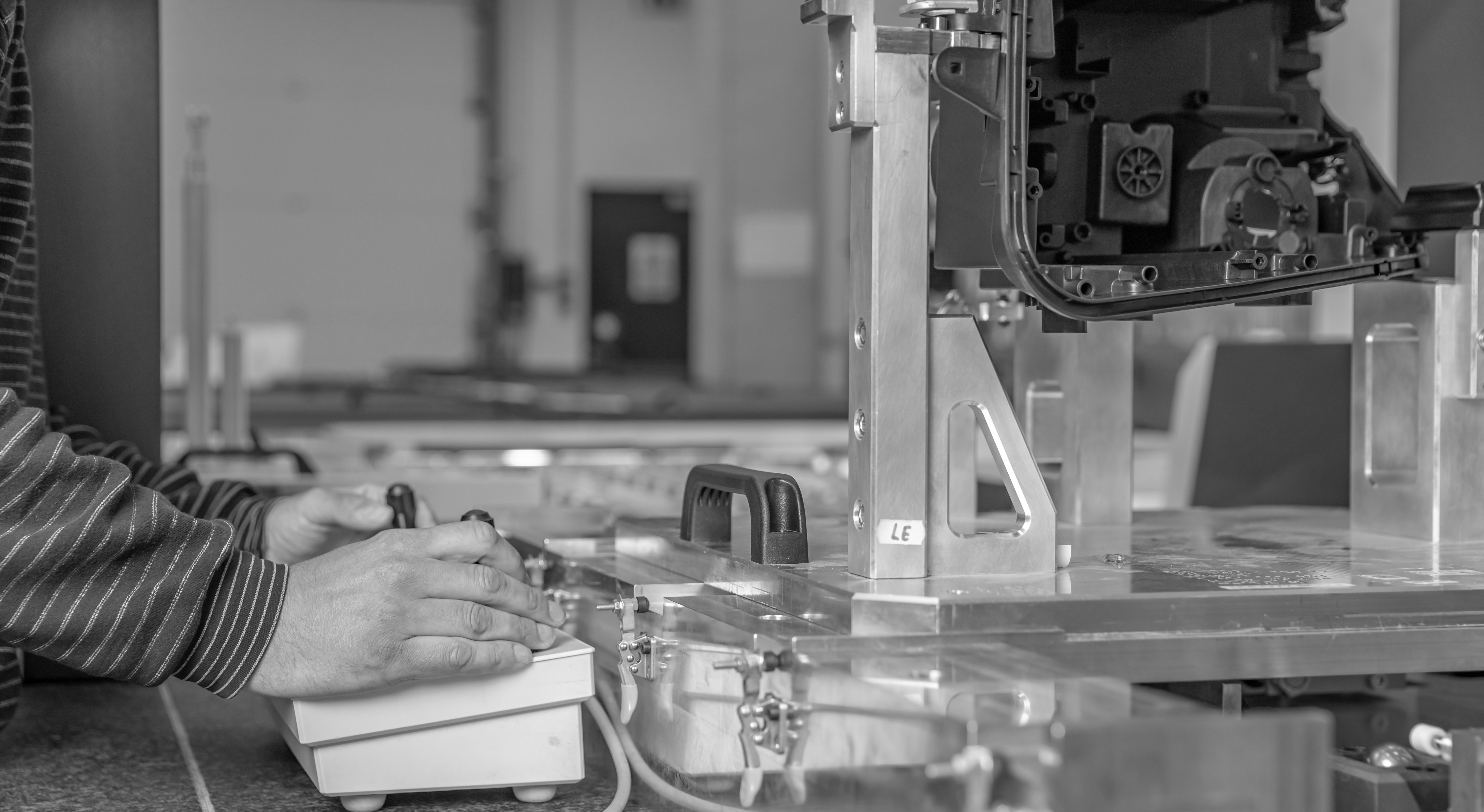

At ATS, we put our expertise at your service to ensure the assembly and installation of your equipment with rigor and professionalism.

Our industrial

assembly services

Equipment assembly

We assemble your machines and equipment with close attention to technical specifications and safety standards. Using advanced measuring tools , we ensure every component is installed correctly, optimizing the overall performance of your production line.

Complete production

lines installation

Our expertise extends to the installation of complete production lines, from planning to commissioning. We coordinate all the steps of the process, integrating the different equipment to ensure a perfect synergy between each element, while respecting the deadlines.

Systems connection

and integration

We connect and integrate the mechanical and electrical system of your industrial facilities. Our expertise covers a wide range of equipment, whether it is isolated machines, production lines or complex installations. We guarantee a precise and secure connection, ensuring the perfect harmonization of the different components.

Heavy and

complex handlings

We are trained to handle the handling of heavy and complex equipment, using appropriate techniques to minimize the risks of accidents. Thanks to our specialized equipment, we can transport and install your machines safely, even in restricted or difficult to access spaces.

Tests and commissioning

Before going into production, we perform rigorous tests to verify that each piece of equipment is working according to specifications. This step allows us to quickly identify and correct any potential problems, ensuring a smooth commissioning and optimal performance from the start.

From idea to achievement, in just one click.

Contact us now to bring your project to life.

Contact usContact us now to bring your project to life.

Our business

sectors

Discover the sectors that we support and the solutions we offer for each domain.

Agri-food industry

Brewing industry

Pharmaceutical and cosmetic industry

Our approach

Project Planning and Preparation

We develop a detailed plan, anticipating each step of the industrial assembly.

Security and compliance

Safety is our top priority. We rigorously comply with all applicable standards and regulations to ensure a safe working environment.

Technical expertise

ATS is composed of 3 technical experts associates who possess a thorough knowledge of mechanical and electrical systems.

Project management

We ensure rigorous project management, coordinating every aspect of the assembly.

Why choose ATS for

industrial assembly?

Experienced team

meeting deadlines

Trusted by leading manufacturers

Performance optimization

Explore our

range of services

Discover all our solutions adapted to your industrial needs, designed to optimize your production and guarantee your success.

We transform your ideas into innovative industrial solutions through a methodical approach covering needs analysis, technical design and performance optimization.

Our industrial maintenance service ensures the reliability and performance of your equipment through preventive and corrective interventions tailored to your needs.

FAQ

For any other questions, feel free to contact us.

Contact usWhat is industrial design?

Industrial design involves imagining, modeling, and developing technical solutions to meet a specific need within an industrial environment. It includes creating plans, defining components, choosing materials, producing 3D models, and anticipating technical, safety, and regulatory constraints.

What are the different types of assembly?

The main types of assembly include mechanical assembly (screwing, bolting, riveting), welded assembly (arc welding, MIG/MAG, TIG), bonded assembly (technical adhesives), snap-fit or interlocking assembly, as well as electrical assembly for connecting components and systems. Each method offers advantages in terms of strength or precision and is chosen based on project requirements and operating conditions.